Application

For Ductile Iron

| Grades | CBN Content | Machining Mode | Workpiece Material | Application |

|---|---|---|---|---|

| UBN S1 | 90% | Interrupted Continuous | Grey cast iron Rough/semi-finish | Roll, surfacing roll repairing, mining machinery,large gear and etc. |

| UBN S2 | 70% | Interrupted Continuous | Hardened steel Rough/semi-finish | Wind power bearing, crankshaft, mining machinery, automobile gear and etc. |

| UBN S3 | 50% | Interrupted Continuous | Hardened steel semi-finish/finish | Crankshaft, drive shaft and etc. |

| UBN S4 | 60% | Interrupted Continuous | Hardened steel/ductile iron/ semi-finish/finish | Gear, shaft and etc. |

| UBN S5 | 75% | Interrupted Continuous | Hardened steel semi-finish/finish | Gear, shaft and etc. |

Remark: Inserts can be customized with special ingredients.

- Workpiece material: High nickel chromium alloy cast iron

- Hardness: HSD78

- Cutting parameters: Vc=55m/min ap=2mm,f=0.2mm/r;

- Grands: UBN S1

- Workpiece material: 42CrMo

- Hardness: HRC42-47

- Cutting parameters:

Vc=150~180m/min,ap=0.2~0.3mm,f=0.08~0.12mm/r; - Grands: UBN S3,UBN S4

Application

For Ductile Iron

| Grades | CBN Content | Machining Mode | Workpiece Material | Application |

|---|---|---|---|---|

| UBN X2 | 85% | Interrupted Continuous | Cast iron Hardened steel semi-finish/finish | Automobile brake disc, Engine cylinder block, Cylinder liner, gear, bear and etc. |

| UBN X3 | 92% | Interrupted Continuous | Cast iron | Automobile brake disc, Engine cylinder block, Cylinder liner, gear, bear and etc. |

| UBN X4 | 85% | Interrupted Continuous | Boron copper cast iron semi-finish/finish | Cylinder liner |

Remark: Inserts can be customized with special ingredients.

- Workpiece material: HT250

- Hardness: HB170-210

- Cutting parameters: Vc=160m/min ap=3mm,f=0.3mm/r;

- Grands: UBN S1

- Workpiece material: Grey Cast Iron

- Grands: UBN X2

- Cutting parameters:

Vc=3000~2500m/min ap=1.5~2.6mm,f=0.1~0.2mm/r;

Application

For Ductile Iron

| Grades | CBN Content | Machining Mode | Workpiece Material | Application |

|---|---|---|---|---|

| UDI Q | Special ingredients | Continuous | Bane of ductile cast iron | Be mainly applied in components which are under complex conditions, and at the same time, which have high requirements for strength, toughness and wear resistance, such as bent axle, camshaft, cylinder liner and engine crankcase for automobile, tractors, heavy duty machinery, internal combustion engine, etc,also be applied in mediun-pressure valve for general machinery. |

Remark: Inserts can be customized with special ingredients.

- Workpiece material: QT400, 500, 600, 800

- Hardness: HB350

- Cutting parameters: Vc=200m/min ap=1mm,f=0.1mm/r;

ADI(Austempering Ductile Iron)Coupling

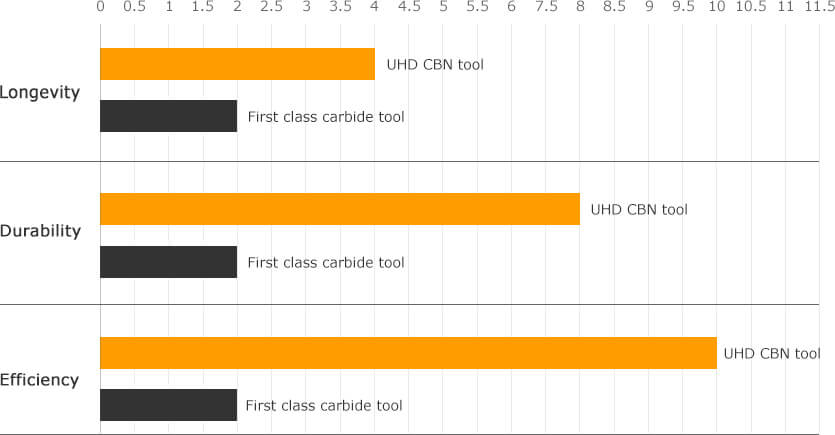

Performance Comparison

Remark: According to the specific machining workpiece and environment, the data will be different.

- Longevity: UHD CBN tools is 2 times longer than foreign brand ceramic tools.

- Durability: UHD CBN tools is 4 times higher than first class coated carbide tools.

- Efficiency : UHD CBN tools is 5 times better than first class carbide tools.

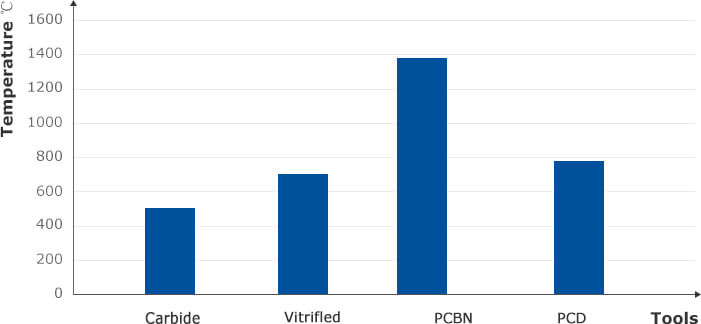

Red Hardness Comparison Of Prevailing Tools

Remark: According to the specific machining workpiece and environment, the data will be different.

- Longevity: UHD CBN tools is 2 times longer than foreign brand ceramic tools.

- Durability: UHD CBN tools is 4 times higher than first class coated carbide tools.

- Efficiency : UHD CBN tools is 5 times better than first class carbide tools.

Why Choose Us

1Capacity

1Capacity20,000 pieces monthly capacity

2R&D Center

2R&D CenterHigh quality control and completed test device

3Superior Efficiency

3Superior EfficiencyToyota cooperated supplier

Production Line

We are proactive and we offer only products complying with top standards of quality and warranty.

Company Profile

UHD ultrahard tools are widely used in mining machinery industry, automotive industry, metallurgical roller machining,

construction machinery, gear and bearing industry, and aerospace industry.

UHD Ultrahard Tools has been supplying superhard products to various customers in different countries and regions, we had been selected and listed into Toyota Supply System. Our products cover the full range of superhard materials, such as cBN, synthetic diamond, and other innovative superhard cutting tools and grinding tools, like PCBN, CVD, diamond wheels and brazed diamond tools. UHD ultrahard tools are widely used into mining machinery industry, automotive industry, metallurgical roller machining, construction machinery, gear and bearing industry, aerospace industry.

UHD ultrahard tools are produced with refined material and we benchmark our products with the best in the word to optimize performance. We also have a progressive quality management system that ensures our produces are of supreme quality. Our premium tools perform brilliantly in the most severe operating environments and assure excellent comfort, elevated safety and longer lifetime.

Our Services

- * Prompt reply and 24 hours online.

- * Professional team to provide best price and high quality product.

- * Sample testing support.

- * Every batch of products will be tested to ensure its quality.

- * The real-time logistics information monitoring.

- * Any questions about the product can be consulted at any time.

- * Product with any problem can return.

- * We offer our clients efficient and considerate service across the world.

FAQ

- Are you a trading company or manufacturer ?We are a professional manufacturer of abrasive tools with more than 30 years’ experience.

- Do you accept OEM brand ?Yes, OEM brand is acceptable. We can also design label for you for free.

- Are samples available for quality test ?Yes, free samples can be sent for quality test, but customers need bear the delivery charge.

- What will I benefit if I cooperate as your distributor ?We will provide special discount and marketing protection to guarantee your benefits and market development.

- What is your package and delivery time ?Standard export package,or according to your requirement;Delivery time is 15 days after we receive the deposit.

- What is your seaport ?All of China seaports are available for us. The basic is Qingdao/Shanghai/Tianjin.

- Can I visit your factory ? And how can I get there ?Yes, welcome to our factory. You can fly to Zhengzhou airport (CGO), we will pick you up.